A look in the history books The company create a new era in construction of Steel structures in it create advantages of Ferro concrete and contributed considerably to the refinement of this industrial materials. The resulting new applications and construction methods form the basis of our successful company history. The company Since 2006, we have been building on this pioneering role in construction under the name of VARMA INDUSTRIAL ENTERPRISES. pipeline construction and large-scale industrial projects helped us through the Great Depression and beyond...

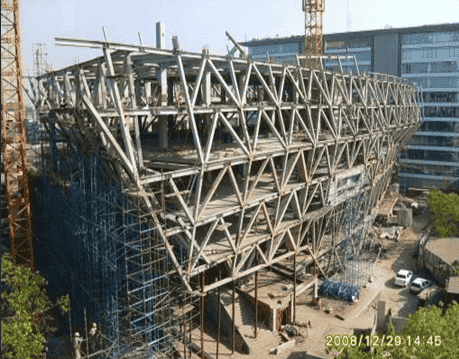

Custom Build Structures for

Custom Fabrication & Erections for

CS Pipes & Tubulars for

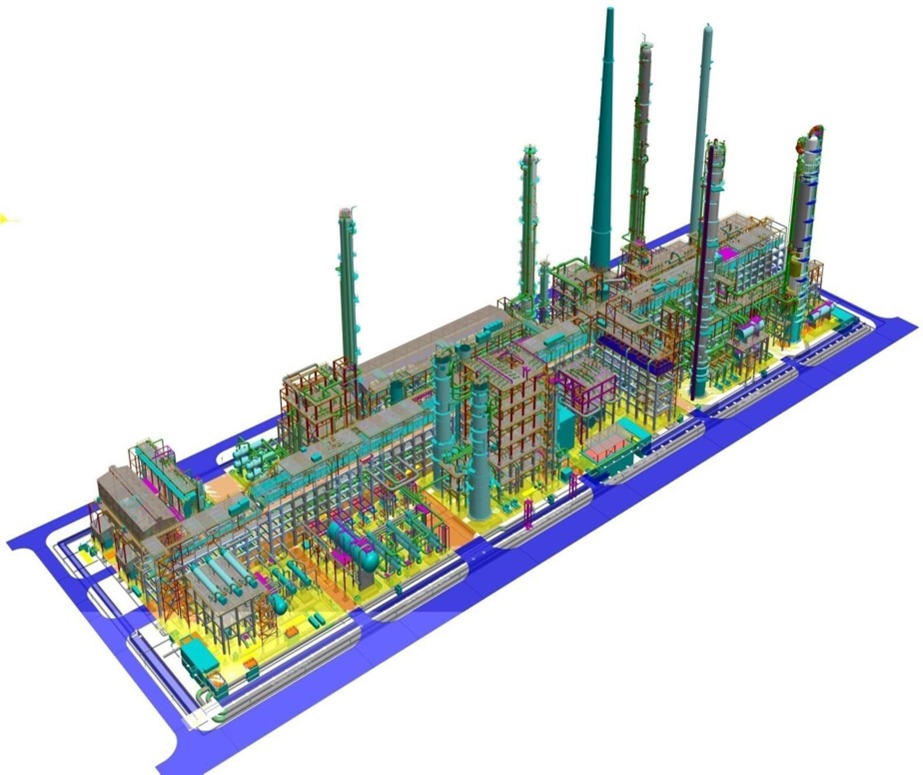

Piping Rack & Technological Structures – Total constructed 7500 MT

| S.no | Name of the client | Scope of work | Location |

|---|---|---|---|

| 1 | Kiran Engineering Service (G F C L - Manpower Supply) | S S Tanks, vessels, pipe line fabrication &erection | Kakinada, A. P |

| 2 | Pipe Line Engineers & Contractors | 20" pipe line IOCL TO Port (8" fire fitting pipe line Manpower contract) | Kakinada, A. P |

| 3 | Kamal Enginneering | 18" pipe line I M C To Poart (Manpower supply/contract) | Kakinada, A. P |

| 4 | Raj Shri Packagers Ltd | Refinery extension, boiler pipe line work | Mangalore, karnataka |

| 5 | Amit Cottons Pvt Ltd | Jinning unit extension Work (Man power contract) | Ajamabad |

| 6 | Good Health Agro Tech Ltd | Refinery extension,Goowns pipe line work(Poart pipe line 12") | Kakinada, A. P |

| 7 | Nikhil Refineries ltd | Storage tanks,structure pipe lines maintennc | Kakinada, A. P |

| 8 | Kedia overseas ltd | Refinery extension ,vanaspathi godown | Kakinada, A. P |

| 9 | Reliance bio fuels ltd (sub contrsct m/s J D constructions) | Solvent plant, seed storage,boilert house | Samalkot, A. P |

| 10 | Palm tech India limited | Pipe line,tanks,structural works | Peddapuram, A. P |

| 11 | G M R Energy ltd (vamagiri power generation ltd) | Fire fitting pipe lines, structural works | VEMAGIRI, A. P |

| 12 | G M R Energy ltd (220mw berge mounted power plant) | Road crossing 18" pipe line,shutter works | Kakinada, A. P |

| 13 | Bloosam Oils limited | D O Erection | Yanam |

| 14 | Siros Overseas Limited | S S tanks,vessols fabrication | Peddapuram, A. P |

| 15 | Madhavi Edible Oils Ltd | Boiler,pipe lines,storage tanks | Mandapeta, A. P |

| 16 | Arani Agro Oils Ltd | Refinery structure,equipment erection | Near port. kakinada |

| 17 | Nikhil Refineries Ltd | 2500 kl Dia 16mtx12.5h storage tank | Near light house. kakinada |

| 18 | Good Health Agro Tech Ltd | Fractination plant structure | Near light house. Kakinada |

| 19 | GMR Power Energy Ltd (Nirmal Industries) | Fual Gas conditioning skid work | Near port. kakinada |

| 20 | Plam Tech India limited | Boiler Modification, pipe lines, storage tanks | Peddapuram, A P |

| 21 | Silk Road Sugors (coramanal consstruction company)Packing house | Fabrication of plant structure | Opp C F L at beach road kkd |

| 22 | Semb Marine Kakinada Limited | Kakinada sea port hydrent system& Storage | Kakinada, A. P |

| 23 | Ruchi Soya Industries Limited | Plant maintenance work | Peddapuram, A. P |

| 24 | Acalmar Oils and Fats Ltd | Laric plant Fabrication | Kakinada, A. P |

| 25 | Agarwal Industries Ltd | S F Plant and boiler modification | Kakinada, A. P |

| 26 | Bhagavathi Edible Oils and Fats Limited | Refinery,boiler all plant works | Kakinada, A. P |

| 27 | Alfa Level India Limited | Refinery,fractination all plant works | Kakinada, A. P |

| 28 | Nagarjuna Fetilizers Limited | Ammonia plant work | Kakinada, A. P |

| 29 | Deepak Nexgen Feeds Private Limited | Structural Material Fabrication, Supply & Erection | Koyyur, Krishna District, AP |

| 30 | Siriman Chemicals India Pvt Ltd | Structural Material Fabrication, Supply & Erection and Machinery Erection | Achyuthapuram, Vizag |

| 31 | Sri Mithra Marine Agencies | Structural Material Fabrication, Supply & Erection and Machinery Erection | Sonya, Vizag |

| 32 | Samira Industries Ltd | Structural Material Fabrication, Supply & Erection and Machinery Erection | Achyuthapuram, Vizag |

| 33 | Sai Marine Exports PV Ltd | Structural Material Fabrication, Supply & Erection and Machinery Erection | Adda road, Vizag |

| 34 | RHI Classily Pvt Ltd | Structural Material Fabrication, Supply & Erection and Machinery Erection | Venkatapuram, Vizag |

In addition, VIE plant facility has area of 50,000 Sq.m is dedicated for raw material storage which can accommodate up to 40,000 ton of steel sections and has fully covered area of 30,000 Sq.m for blasting and painting operation that can easily handle any of your project coating requirements. The plant is equipped with the latest technology of CNC machine, welding machines, blasting machines and other types of equipment to ensure the quality, speed of production accuracy, and proper control. The plant has also No. off Overhead Cranes & Ground Trolleys for Material Handling during the production.

In addition to the production capabilities described above, all the engineering and quality control is carried out in-house, with the additional independent third-party testing of welds, in compliance with approved specific project ITP (Inspection and Test Plans), undertaken by Internationally Recognized and Approved Testing Agencies.

| S.no | Client | Qty. (MT) | Components |

|---|---|---|---|

| 1 | YASH VEGETABLE OILS LTD – Thermax Ltd.(6.0 TPH Boiler & Themopac) | 16403 | Primary Steel Structures & Top Girder Steel Structure Primary Steel – Air Pre Heater Structure, Secondary Boiler Supporting Structure |

| 2 | YASH VEGETABLE OILS LTD – Thermax Ltd.(6.0 TPH Boiler & Themopac) | 1395 | Primary Steel Structure, Supply of Boiler Main Steel Structure |

| 3 | YASH VEGETABLE OILS LTD – Thermax Ltd.(6.0 TPH Boiler & Themopac) | 15500 | Supply of Boiler Components – Complete Boiler inclusive of Columns , Auto Welded Beam & Boxes, Ducts, General Fabrication items |

| 4 | YASH VEGETABLE OILS LTD – Thermax Ltd.(6.0 TPH Boiler & Themopac) | 15000 | Boiler Primary Structure & Ceiling Girders |

| 5 | RELIANCE INDUSTRIES LTD. | 9000 | Pipe Racks & Technological Structures for Gasification Plant Jamnagar Refinery Expansion Phase 3 |

| 6 | YASH VEGETABLE OILS LTD – Thermax Ltd.(6.0 TPH Boiler & Themopac) | 2281 | CDU/VDU Heater of Phase III Exp. Project of MRPL – Mangalore |

| 7 | Essar / GR Engg | 3500 | Equipment Support Structures for Reactor Regenerator Integrated Refinery Expansion BPCL, Kochi |